We make things. Better.

Safety Barriers and Suspended Walkways: Where and Why Your Business Needs Them

C&C Fabrications, December 2024

- Having the right equipment in your workplace could make the difference between life and death – literally!

- When it comes to health and safety, compliance with regulations is not an option, but necessary.

- Depending on your industry, products such as safety barriers and suspended walkways are some of the core aspects of keeping your team safe, from manufacturing and logistics to construction and retail.

In this article, we’ll explore the importance of these products, the regulations surrounding their use, and how other essential safety items like steel metal brackets and sheet metal ramps can enhance workplace safety – all which C&C have years of experience fabricating and supplying.

Why Safety Barriers Are Essential

Safety barriers are a must-have in environments where pedestrians and vehicles coexist. They help define clear boundaries, prevent accidental collisions, and protect workers from machinery. Whether used in warehouses, car parks, or manufacturing facilities, these barriers are a key investment in creating a safe and efficient workspace.

Why Suspended Walkways Are Essential

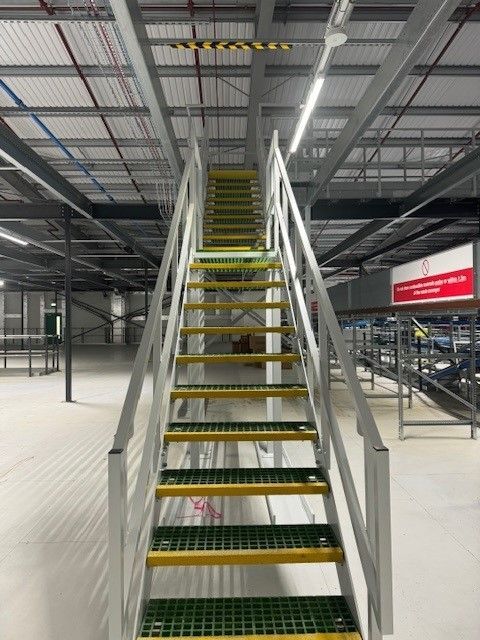

Suspended walkways are invaluable in settings where workers need safe access to elevated areas. These walkways minimise risks associated with falls and ensure compliance with stringent safety regulations.

Common in construction, maintenance, and industrial facilities, they provide a secure way to access hard-to-reach areas. Our fabrication expertise includes components like track frames and brackets for suspended systems. These products allow for precision and durability in essential health and safety equipment.

Other Workplace Safety Essentials

While safety barriers and suspended walkways are crucial, they’re just a part of a broader range of health and safety products your business might need. Here are two more items every workplace should consider:

Steel Metal brackets

Steel brackets are versatile components used to secure structures like walkways, barriers, and shelving units. Their strength and durability make them a staple in health and safety solutions.

For our client Enable Access, we manufactured main axle brackets and various track frames as part of their stock order. We take pride in crafting bespoke items like this, to meet the custom fabrication needs of clients building a safer and more accessible society and industry, especially in meeting specific safety requirements.

Sheet Metal Ramps

Sheet metal ramps are so important for creating accessible environments, whether for staff, customers, or logistics operations. They provide safe and stable access to elevated surfaces or across uneven terrain.

We’ve also delivered numerous ramps, fabricated in various sizes for varying different clients and need. These ramps are designed to withstand heavy use while maintaining a sleek and functional appearance.

Where You’ll Find These Products in Action

The products we fabricate are used in diverse environments, including:

- Warehouses: To separate pedestrian walkways from forklift paths with safety barriers.

- Construction Sites: For secure access to elevated workspaces with suspended walkways and ramps.

- Retail and Commercial Premises: To ensure accessibility with custom ramps and brackets.

Real-Life Examples of How C&C Have Helped

At C&C Fabrications, we take pride in delivering bespoke solutions that enhance workplace safety and efficiency. Here are a couple of real-life examples of how we’ve worked with leading companies to improve access, safety, and operational functionality:

Improved Access and Increased Safety for Maintenance Teams at Next

For Next PLC, we designed and fabricated bespoke access solutions to improve the safety and efficiency of their maintenance teams. By creating secure walkways and elevated platforms, we ensured that workers could safely access elevated machinery and hard-to-reach areas, minimising the risk of falls and accidents. Read more on this case study here.

Creating Space and Improving Safety for DS Smith

For DS Smith, we developed tailored safety barriers and suspended walkways to create safer workspaces and more efficient operations. Our custom solutions helped organise busy areas, providing clear separation between pedestrian pathways and machinery, ensuring compliance with safety regulations and improving overall workflow. Read more on this case study here.

Find more case studies on how we’ve helped multiple businesses with their platforms and walkways.

Meeting Health and Safety Regulations

UK businesses must comply with strict health and safety regulations, including the Health and Safety at Work Act 1974 and the Workplace (Health, Safety and Welfare) Regulations 1992. Installing products like safety barriers, suspended walkways, and ramps ensures compliance while safeguarding employees and visitors.

At C&C, our products are designed to meet these regulations and exceed expectations. With a focus on quality, durability, and innovation, we’re proud to help businesses create safer workplaces.

Let’s Build a Safer Future Together

At C&C Fabrications, we specialise in bespoke health and safety solutions, from steel metal brackets to sheet metal ramps, designed to meet the unique needs of your business. Our precision-engineered products help create safer workplaces by ensuring compliance and protection for your team.

Ready to improve the safety of your environment? Contact us today, and let’s discuss how we can provide tailored workplace safety solutions that work for you.

Ahead of the curve: preparing for the future.

C & C Fabrications have been providing high-quality, highly-skilled metal fabrication for over 25 years. We offer an end-to-end comprehensive service of consultancy, design and manufacturing, and have the skills and resources to deliver a quality result.

We have experienced massive growth in the past few years and have expanded to 28 employees, and are now looking to the future of C & C. As part of our growth plans we have reinvested in our brand and our people through the creation of a new, easy to navigate, website and a company rebrand to represent our continuing evolution and the pride that we take in the work that we do.

Our re-brand is more than just a fresh look; it establishes our professionalism and redefines the standard. We see this as an opportunity to re-state C & C’s culture of excellence and service – both internally and externally. Our re-brand shows our customers, prospects and suppliers that we mean business.

As the company grows, so does our capability, here at C & C we believe in matching our talent with the right tools and so have invested half a million pounds in a new, state of the art Laser Cutter.

Welcome to the cutting edge; welcome to the Kimla Powercut 6kw Fibre Laser Cutter.

Rapidly efficient, the Kimla Powercut’s speed beats a traditional Co2 machine 8 times over; this means reduced lead times, accurate cutting of sheet metal up to 20mm and a complete in-house laser cutting service. For our customers this new technology means a faster delivery of projects that remain the same high quality as before.

As a growing company C & C are proud to say that we have accelerated our expansion, anticipating and meeting industry expectations whilst keeping the customer front of mind, always. The recent changes that we have made to our brand and technology mean better, more efficient service for your company with a brand that has clarity, ambition and strives to deliver the quality it promises.

To hear more about what we can do for you call Gary on 01977 670067 or email gfirth@candcfabrications.co.uk