Circular Floor Covering with Aluminium Durbar for a Yorkshire Warehouse

Circular Floor Covering with Aluminium Durbar for a Yorkshire Warehouse

C&C Fabrications, January 2025

Aluminium Durbar Installation for Safety and Maintenance

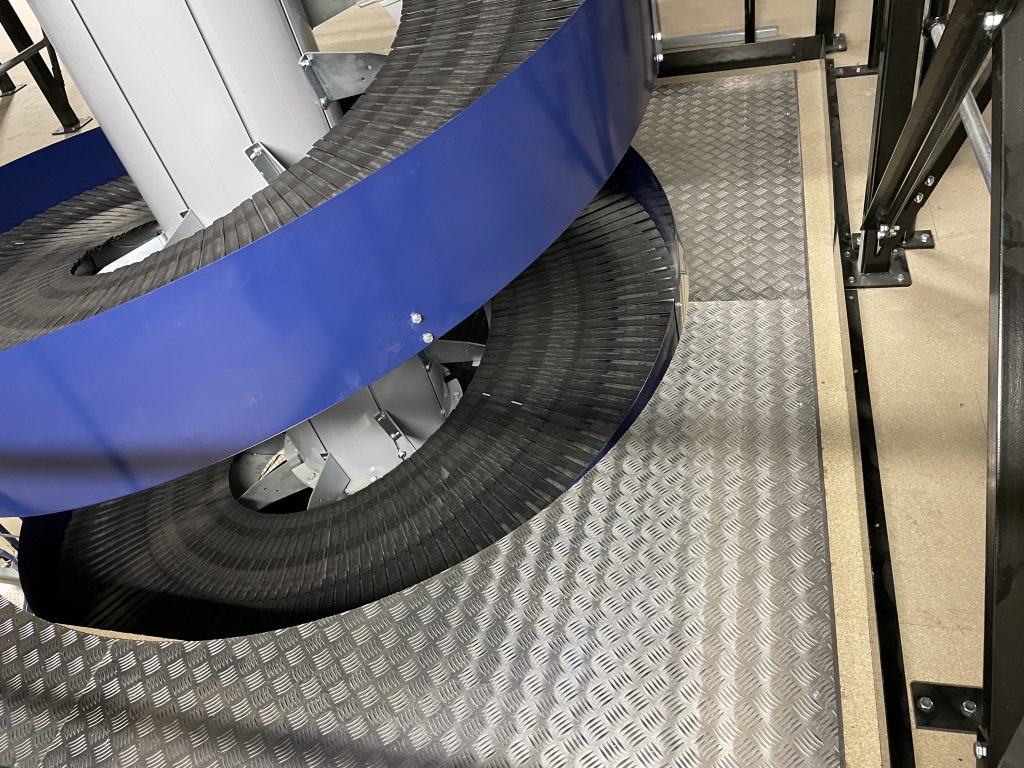

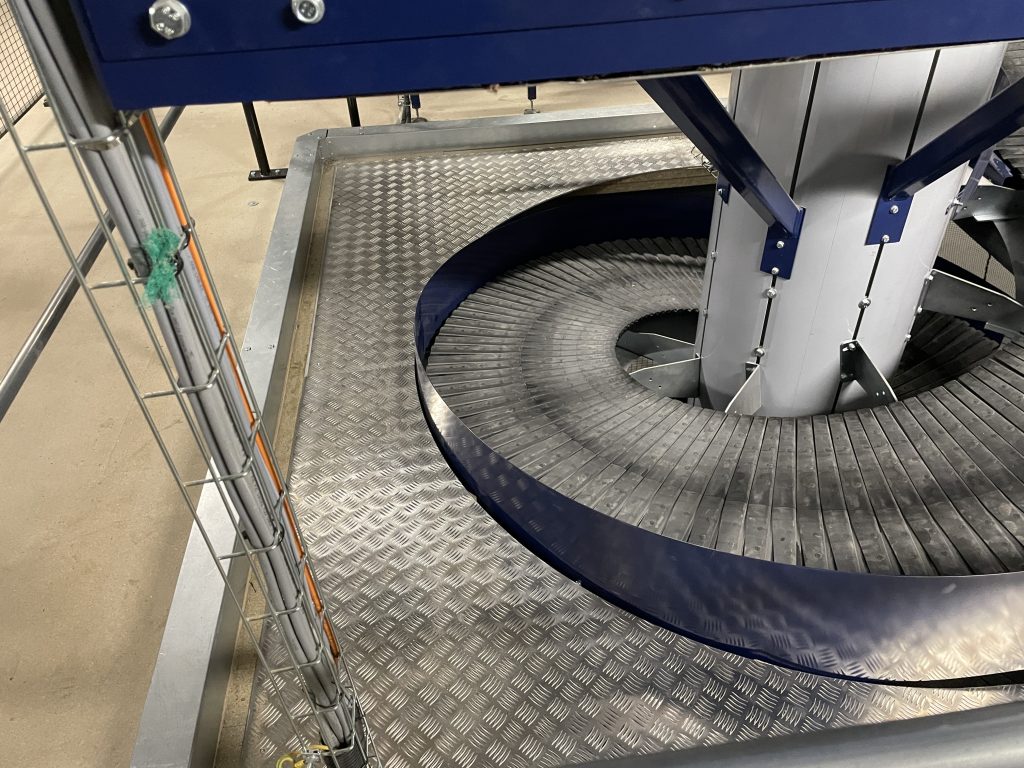

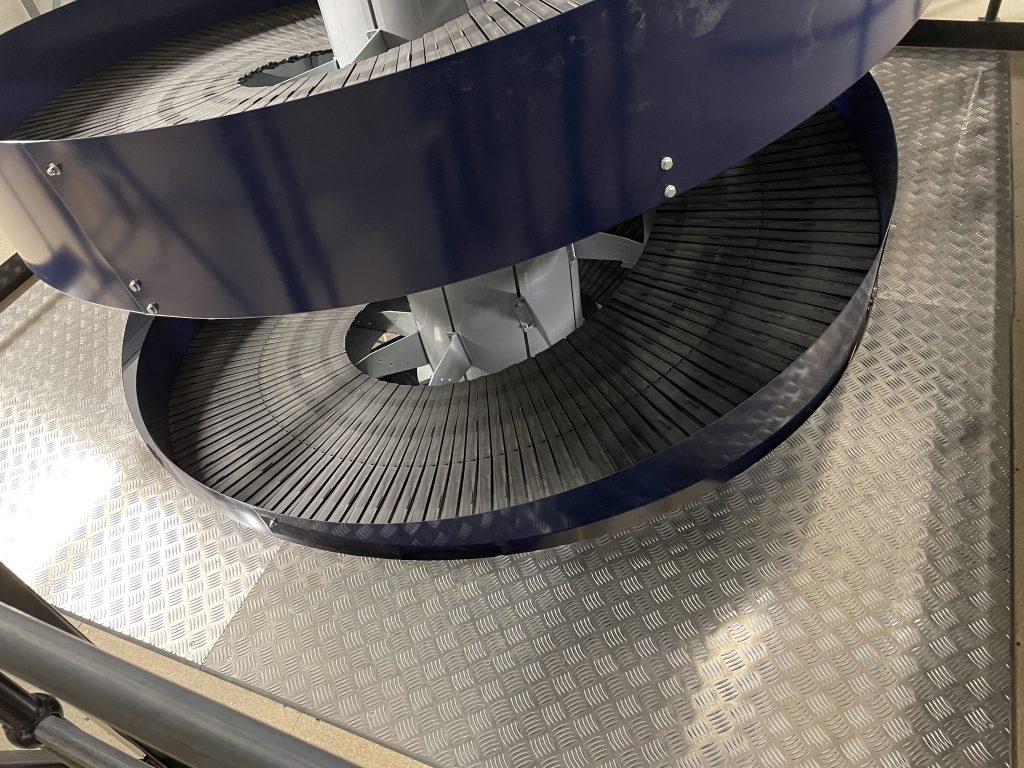

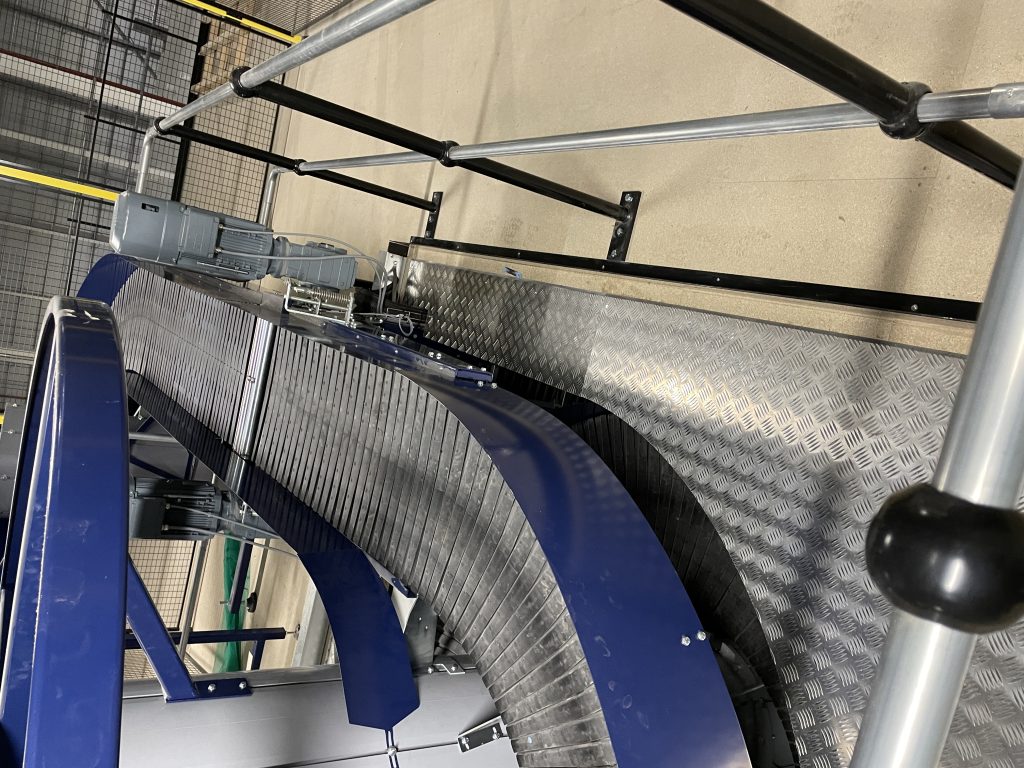

At C&C Fabrications, we specialise in delivering customised metal fabrication solutions that combine functionality and durability. When a warehouse in Yorkshire required a solution to improve safety and maintenance access around their conveyor chutes, we were proud to provide a robust, bespoke floor covering system.

The Challenge – Enhancing Safety and Maintenance Access

The Challenge – Enhancing Safety and Maintenance Access

- The client needed a durable and practical solution to cover the exposed floor edges around conveyor chutes.

- The goal was to ensure staff safety by reducing trip hazards and providing secure access for maintenance.

- The material used needed to withstand heavy industrial use while requiring minimal upkeep.

“We knew this project demanded precision and reliability. Every detail had to be spot-on to meet the client’s needs,” said Bryan Lee, Design Engineer at C&C.

The Solution – Aluminium Durbar for Strength and Reliability

At C&C Fabrications, we understand the importance of selecting the right material for each project. For this warehouse floor covering, we recommended Aluminium Durbar due to its exceptional properties that make it ideal for industrial environments.

At C&C Fabrications, we understand the importance of selecting the right material for each project. For this warehouse floor covering, we recommended Aluminium Durbar due to its exceptional properties that make it ideal for industrial environments.

Why Aluminium Durbar?

- Slip Resistance: The raised pattern on Aluminium Durbar provides a superior grip, reducing the risk of slips and falls in high-traffic areas. This feature is critical for ensuring staff safety around conveyor chutes.

- Durability and Strength: Aluminium Durbar is lightweight yet incredibly robust, making it capable of withstanding the heavy wear and tear typical of industrial settings.

- Corrosion Resistance: Unlike many other metals, Aluminium Durbar resists rust and corrosion, even in damp or challenging conditions. This ensures longevity and minimises the need for maintenance.

- Ease of Fabrication: Aluminium Durbar is highly workable, allowing our team to shape and customise it to fit precisely around the unique layout of the conveyor chutes.

”From experience, Aluminium Durbar was the perfect choice for this job. Its grip and durability ticked every box,” added Lee Reed, Designer Engineer at C&C.

Our team designed and fabricated a customised floor covering system to seamlessly integrate with the conveyor layout. Once fabricated, the Aluminium Durbar was installed on-site to deliver a safe and efficient solution.

The Result – A Safer, More Efficient Workplace

The Result – A Safer, More Efficient Workplace

- The Aluminium Durbar installation significantly enhanced the warehouse’s operational safety.

- By covering the exposed edges around the conveyor chutes, the risk of workplace accidents was minimised.

- Additionally, the new floor covering provided easy and secure maintenance access, ensuring uninterrupted operations.

Our ability to deliver durable, low-maintenance solutions demonstrates why C&C Fabrications is a trusted name in not only smaller custom metal fabrication, but even large-scale bespoke metal fabrication.

The client was more than delighted, remarking, ”the new flooring has made a real difference. It’s practical, safe and exactly what we needed.”

Why Choose C&C Fabrications?

At C&C Fabrications, we turn ideas into reality with expert craftsmanship and tailored solutions. From industrial flooring to intricate custom designs, we deliver high-quality results that exceed expectations. For more insights, take a look at some of our other case studies here.

If you’re looking for a partner to bring your next project to life, get in touch with us today.

Circular Floor Covering with Aluminium Durbar for a Yorkshire Warehouse

Circular Floor Covering with Aluminium Durbar for a Yorkshire Warehouse The Challenge – Enhancing Safety and Maintenance Access

The Challenge – Enhancing Safety and Maintenance Access  The Result –

The Result –